Best compliance to ISO 9001 standards

Inward Quality Control:

- Pre-Dispatch Inspection Report

- Inward Bag Tagging System for traceability and FIFO

- Component Specification; Limit Samples; Sampling Plan; Calibrated Tools & Gauges

- Fit / Form / Functional testing of inward lots

- Test Certificates of Raw Materials

- Accepted Quality Limit and Agreement of Inspection

- Vendor Evaluation & Quality Sustenance Audits along with Vendor Portal system for seamless communication and transparency

- SCAR & FMEA

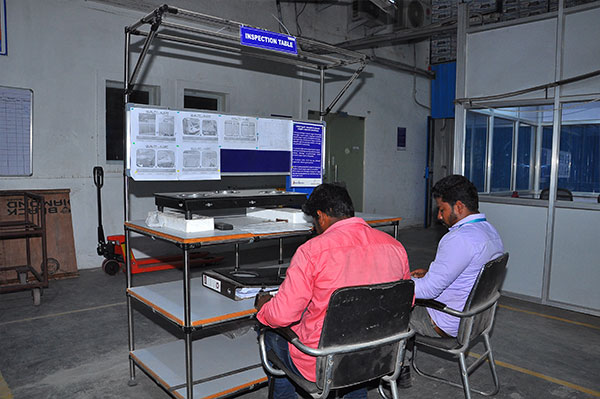

In Process Quality Control:

- Process Control Plan

- Standard Operating Procedure

- Critical to Quality stage definition

- Zero Hour Defect analysis,

- Communication mechanism to process owners on defects for corrective actions

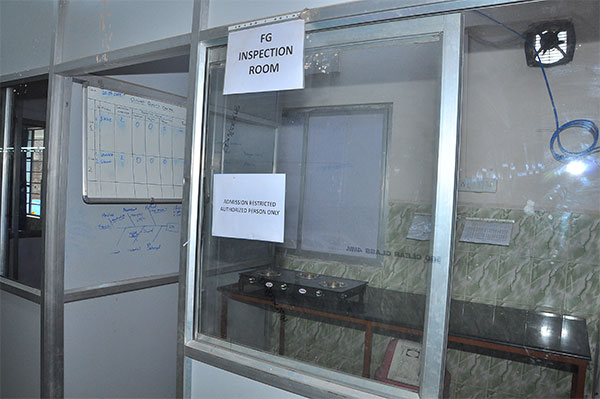

Outward Quality Control:

- Fit / Form / Functionality tests on finished goods as per sampling plan and AOI

Lot approval status based on AQL and standards with the customers